IDEA Statica Steel Connection

Steel connection design – reinvented Start your 14 day trialJoin the next webinarA novel way to design and check all steel connections according to the code, in minutes.

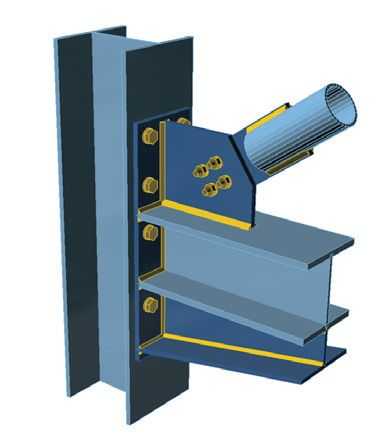

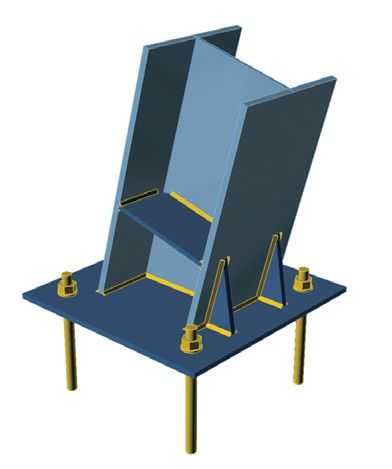

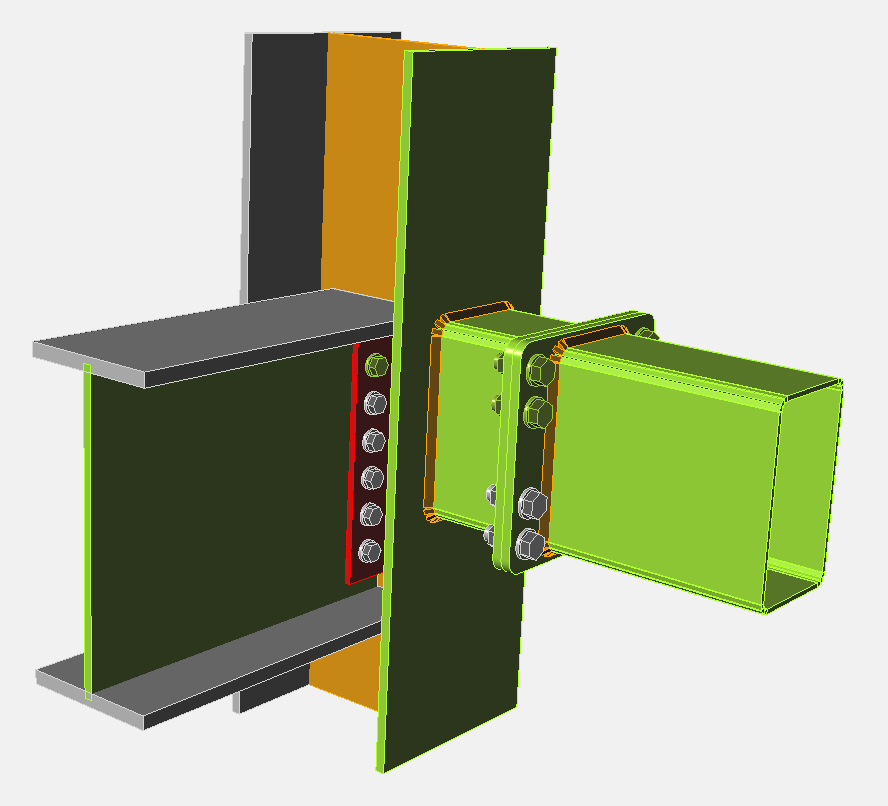

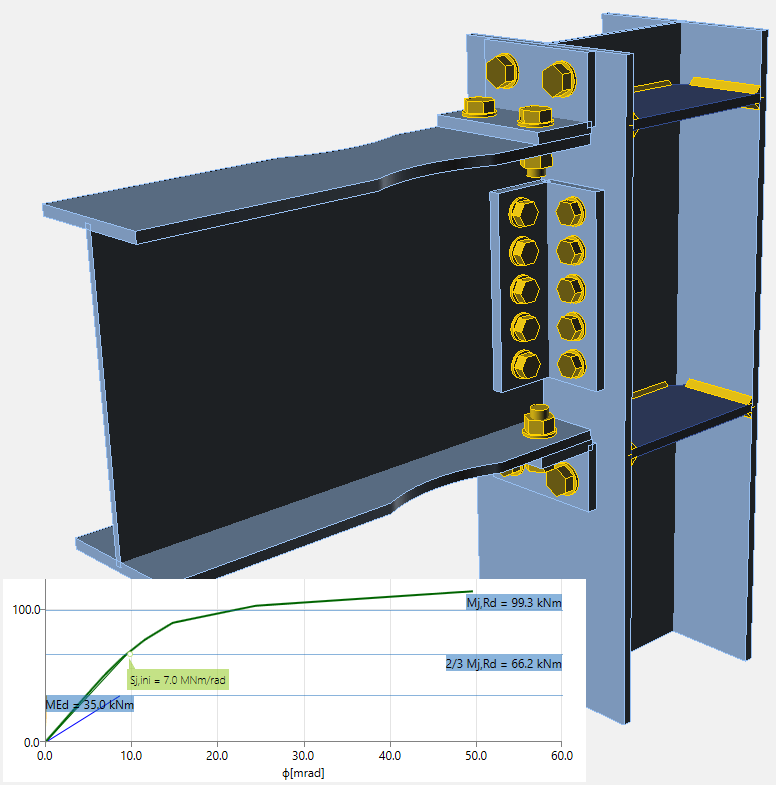

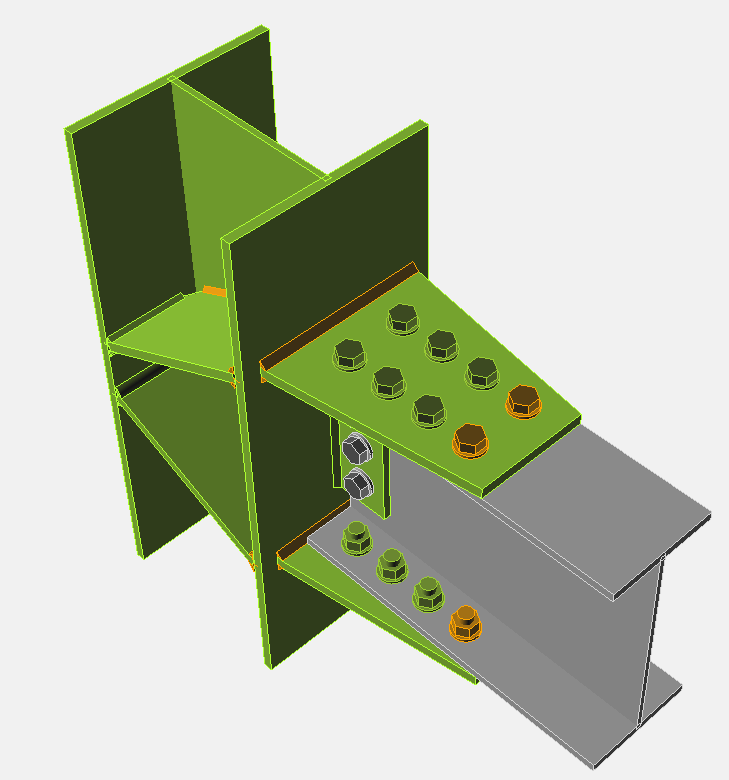

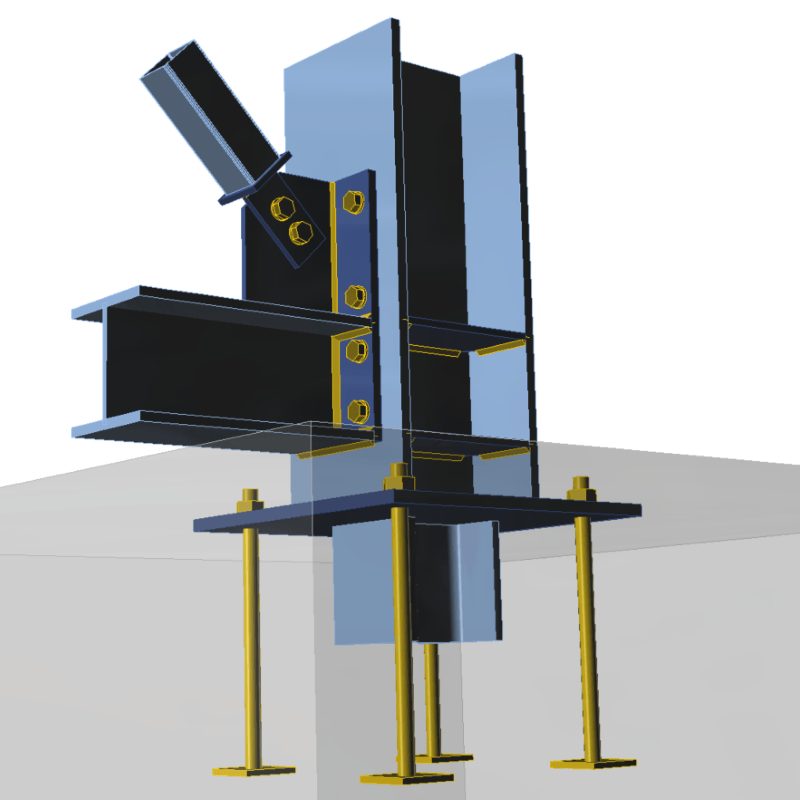

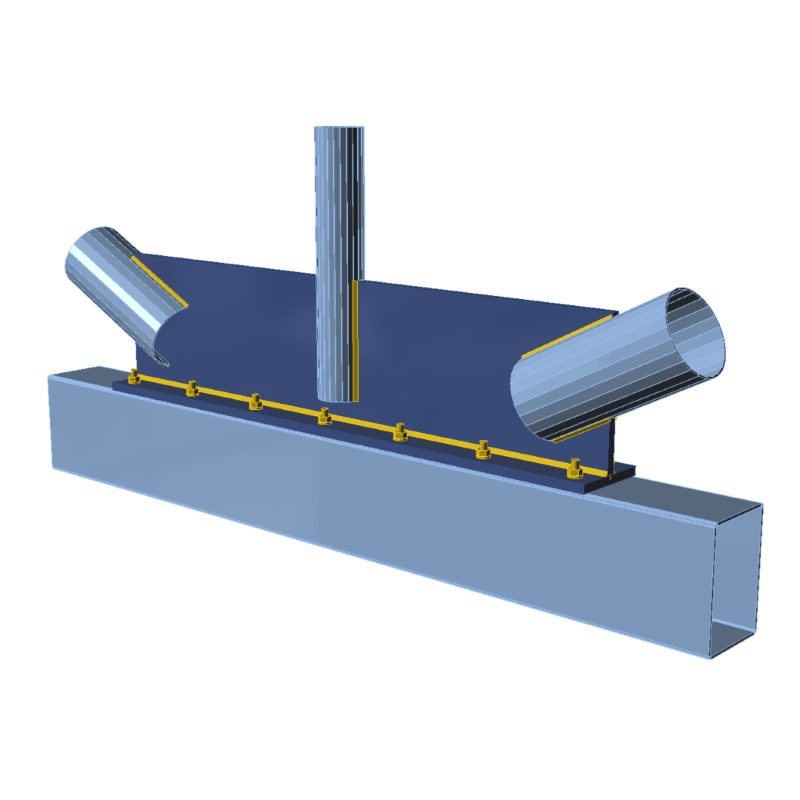

IDEA StatiCa Connection can design all types of welded or bolted connections, base plates, footing and anchoring. It provides precise checks, results of strength, stiffness and buckling analysis of a steel joint. Bolts, welds and concrete blocks are checked according to EC/AISC. Templates for most-used connections are available as well as wide range of predefined hot rolled and sheet welded members.

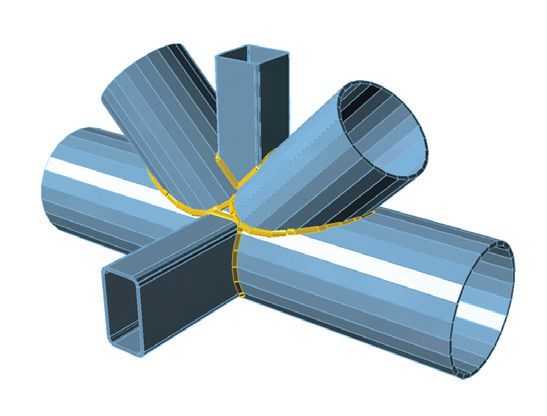

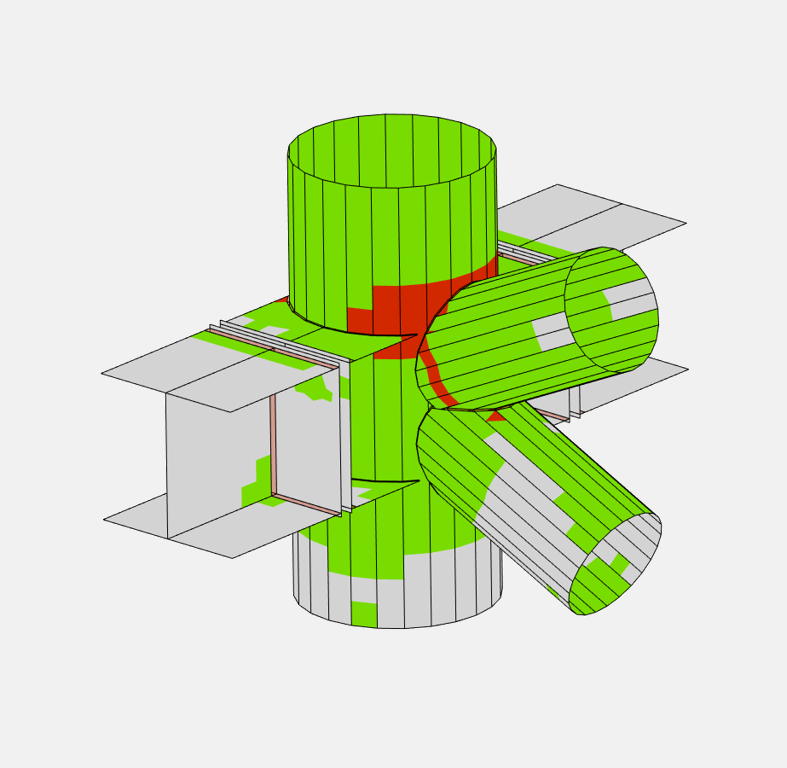

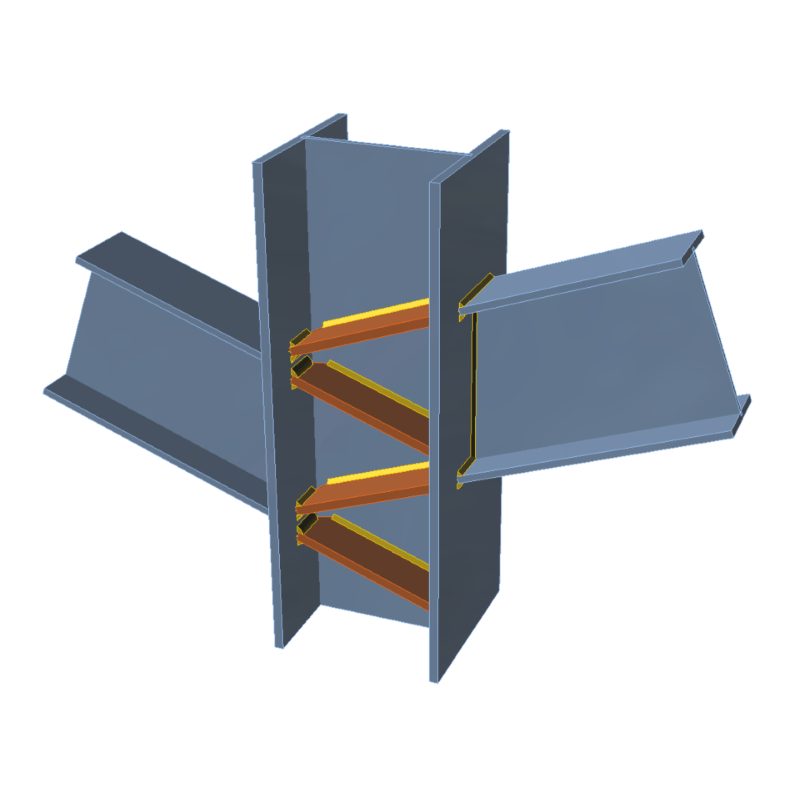

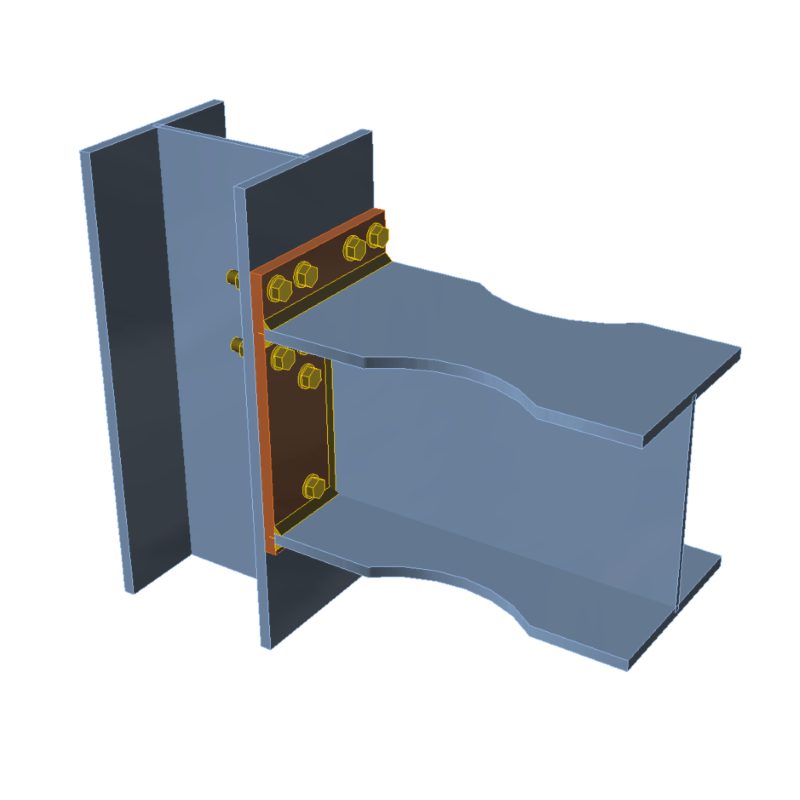

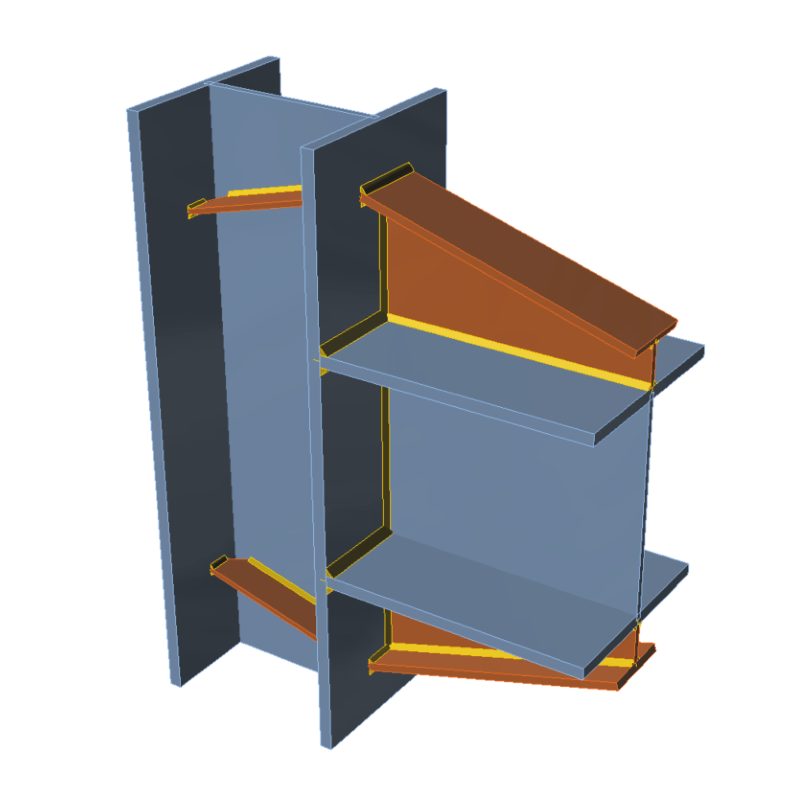

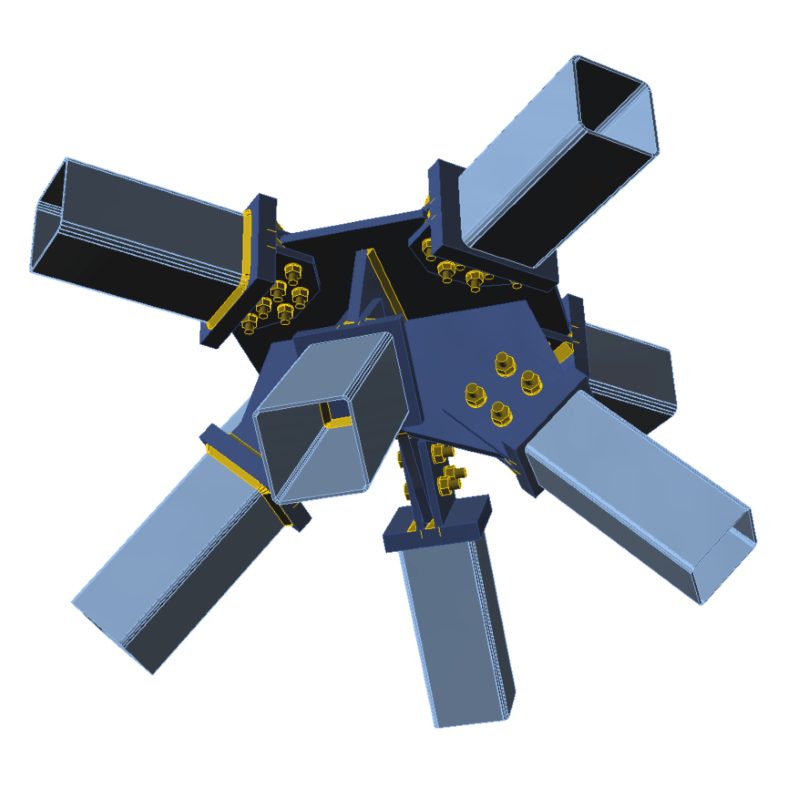

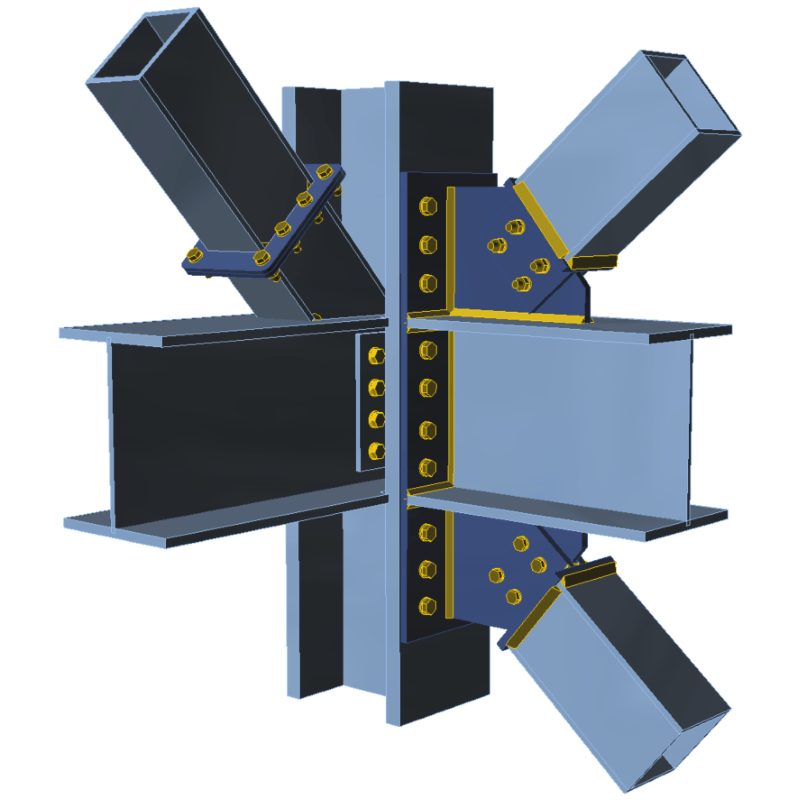

ANY TOPOLOGY

No limits in how many connections there are in the joint and how they are put together. Shape is defined by project requirements, not by software capabilities.

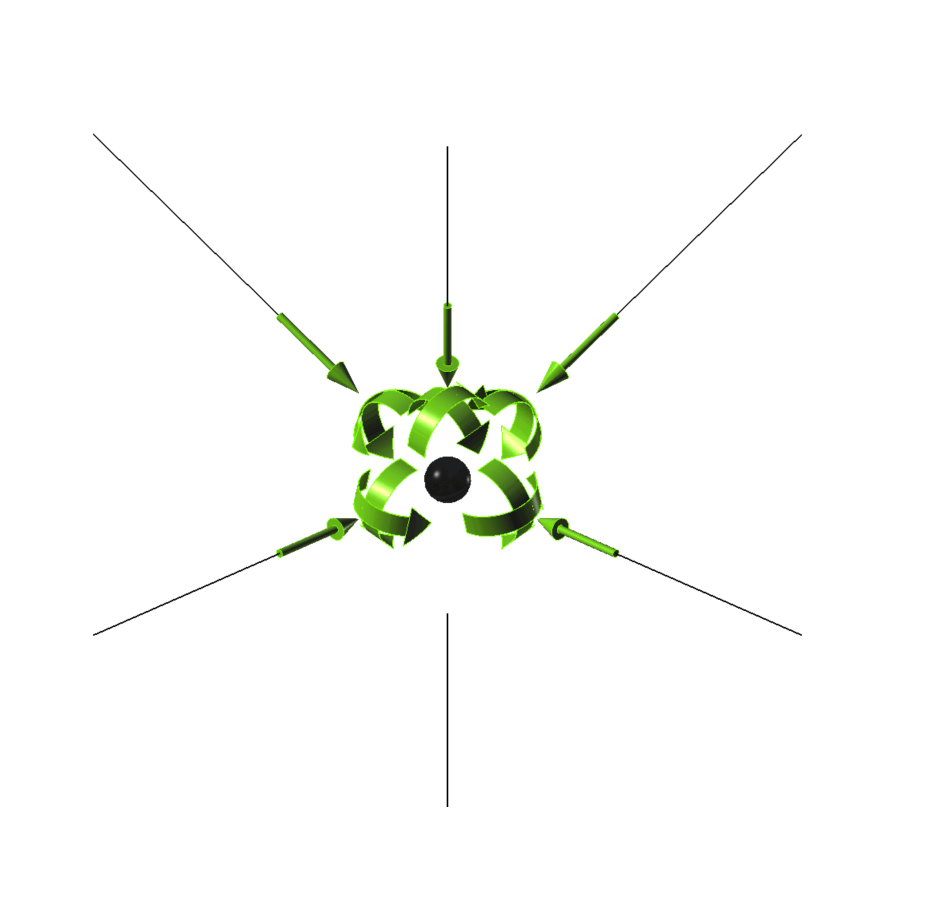

ANY LOADING

All forces are analyzed. The overall check of the joint takes into account interactions between all the beams and connections. Engineers stay on the safe side all the time.

IN MINUTES

The whole design and check process is kept short enough to be a part of everyday work of structural engineers and fabricators all around the world.

IDEA StatiCa Connection provides

Work with data from other programs

IDEA StatiCa Connection

FEA SOFTWARE

Design your joint from scratch or build on geometry and loading imported from Robot, Revit, MIDAS Civil + Gen, STAAD.Pro, SAP 2000, Scia Engineer, RFEM, RSTAB, AxisVM, ConSteel, and others, cutting design time even more.

CAD SOFTWARE

Take advantage of integration into Tekla Structures and Advance Steel to provide workshops drawings and support manufacturing process.

Improving daily work of engineers

IDEA StatiCa Connection can design steel joints and connections of any topology and loaded in all directions. It keeps the whole

analysis-design-check process in minutes. This opens a possibility for structural engineers and fabricators around the world to

increase productivity of designing steel joints and connections.

BE SAFE

Stay on the safe-side with all checks according to selected national codes at hand at any time.

SAVE TIME

Engineers spend 70% of the connection design time on 30% non‑standard cases. Do them in minutes as well.

OPTIMIZE

Know exactly how much material is needed in the joint and take advantage of it.

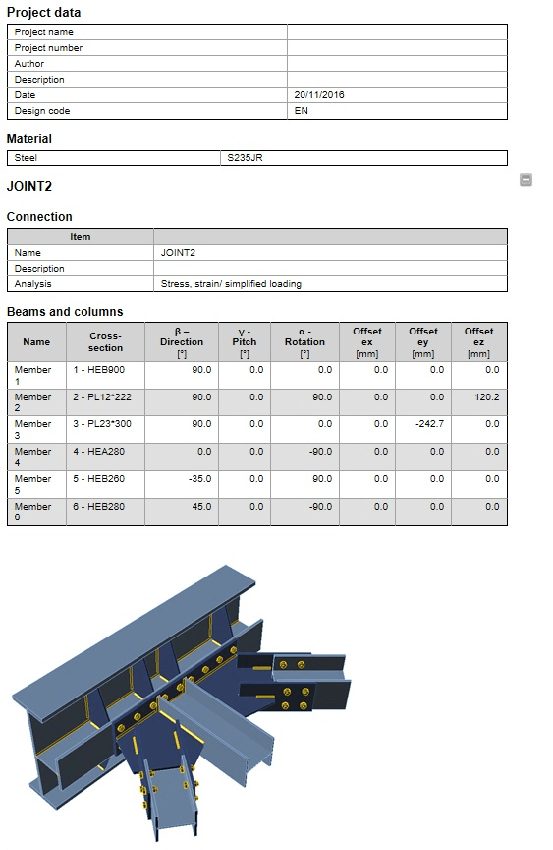

Output report

You can choose from three types of output reports – one line, 1 page and detailed. All checks according to Eurocode or AISC are displayed and referenced.

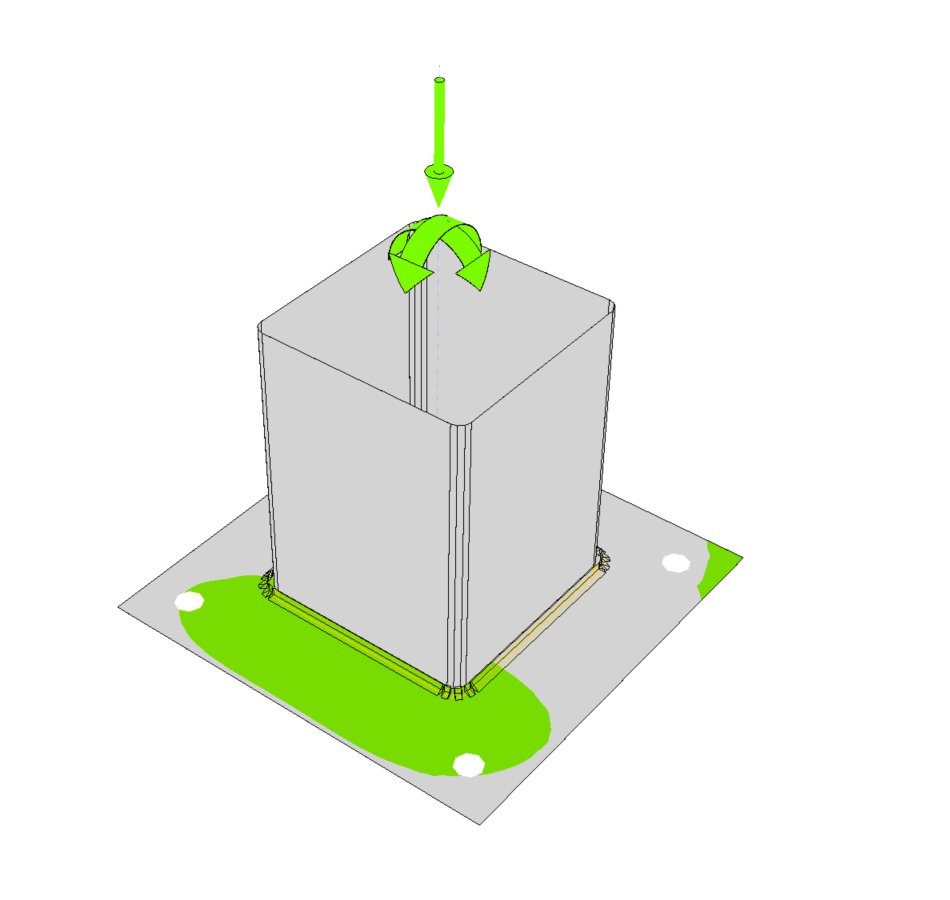

Any topology – manufacturing operations

Any loading – all internal forces from 3D global analysis

Any loading – all internal forces from 3D global analysis

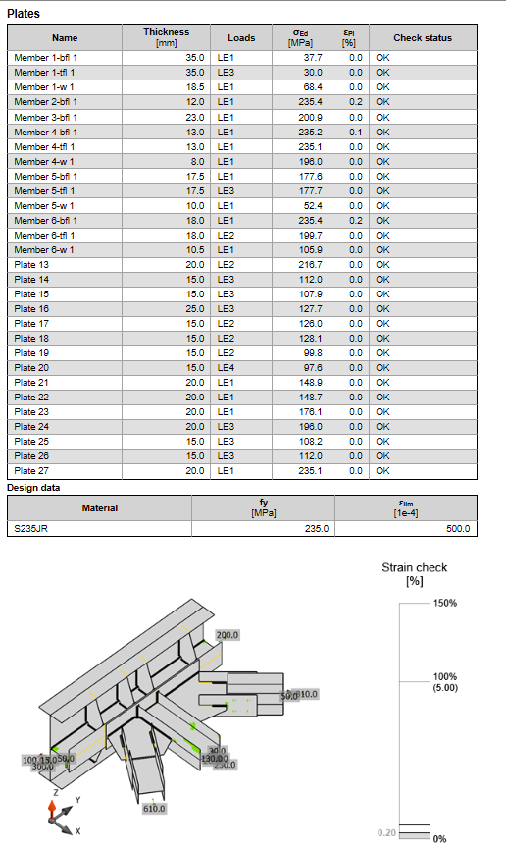

Plates

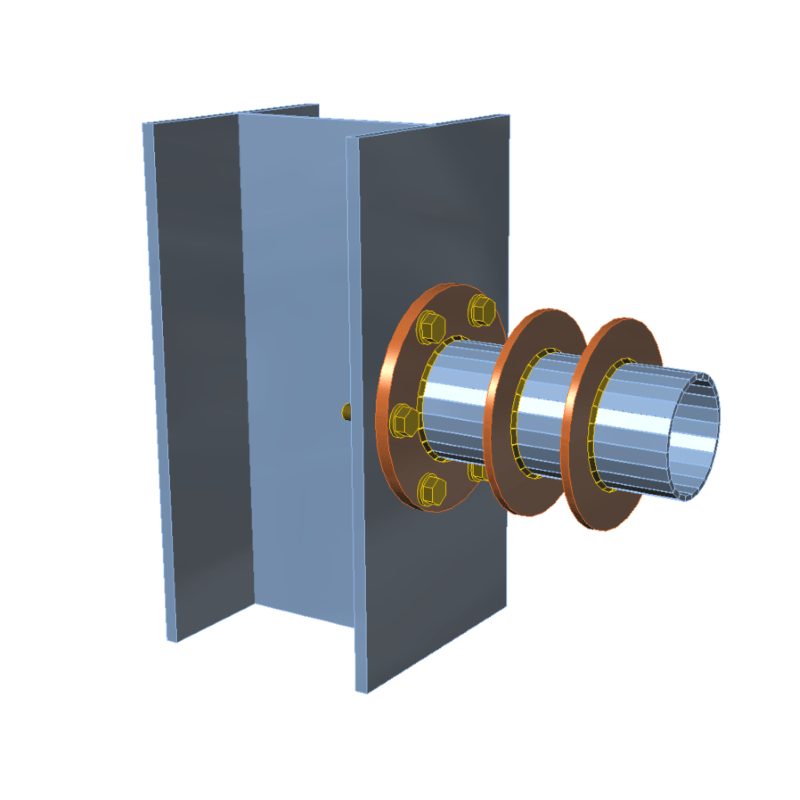

Contacts

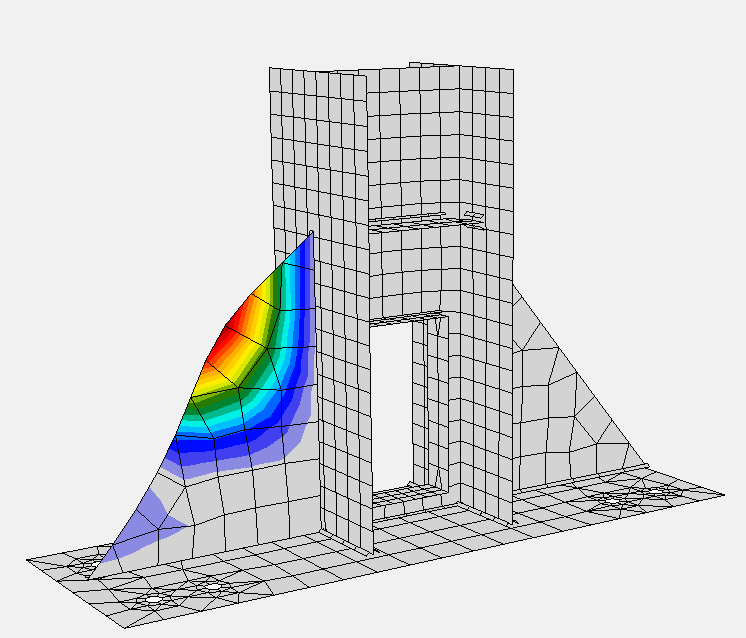

Concrete block

Steel structure can be anchored into concrete block. Base plate is in contact with concrete. Tension is taken by anchors, shear by bolts, friction or shear iron.

Designed by IDEA Statica Connection

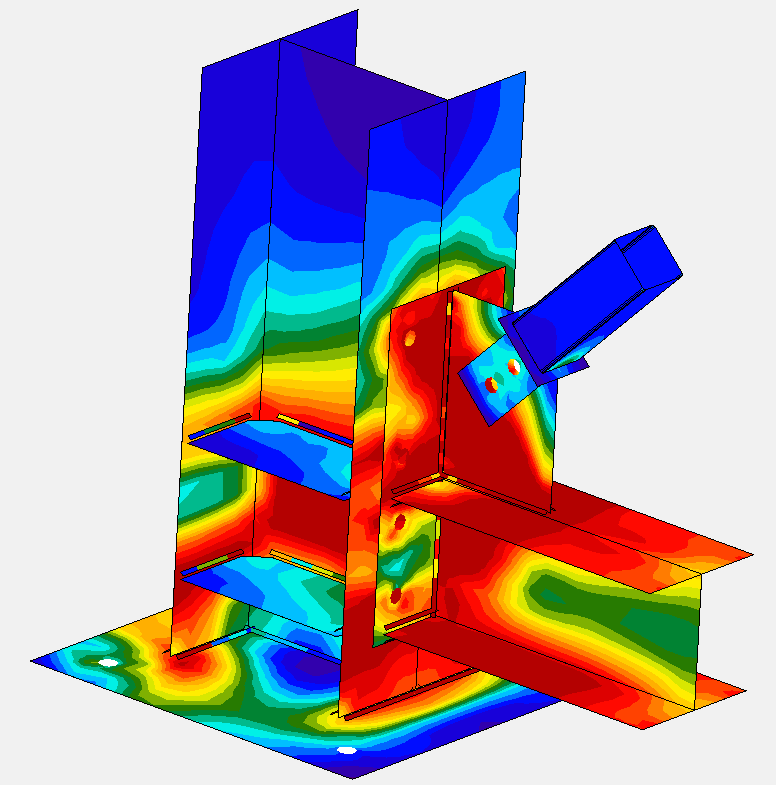

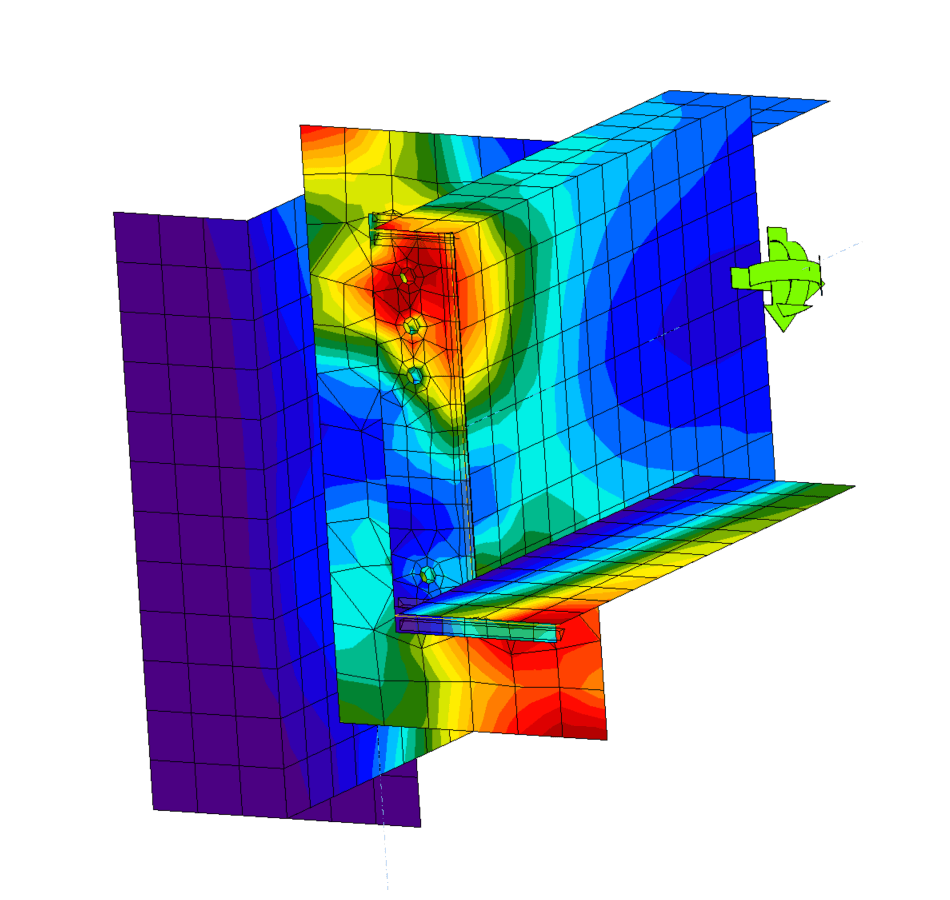

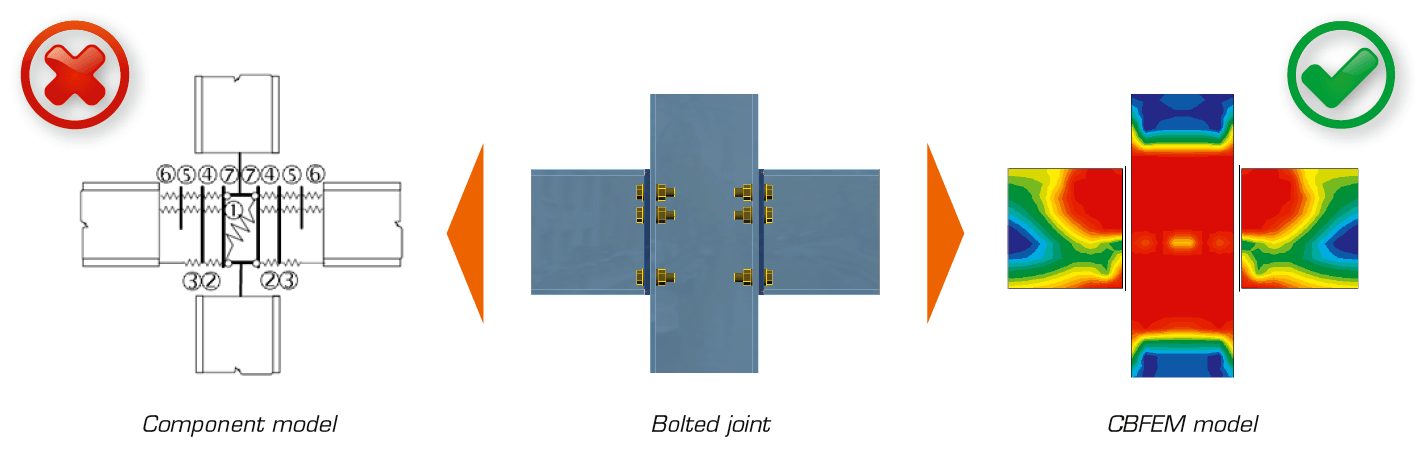

New CBFEM method inside changes the game of structural joint design

Together with two top technical universities, we created a new method for analysis and check of steel joints of general shapes and loading. It is called Component-Based Finite element model (CBFEM). After 5 years of primary research and theoretical preparations, the first version of the application was coded in 24 months and released in May 2014.

How CBFEM works

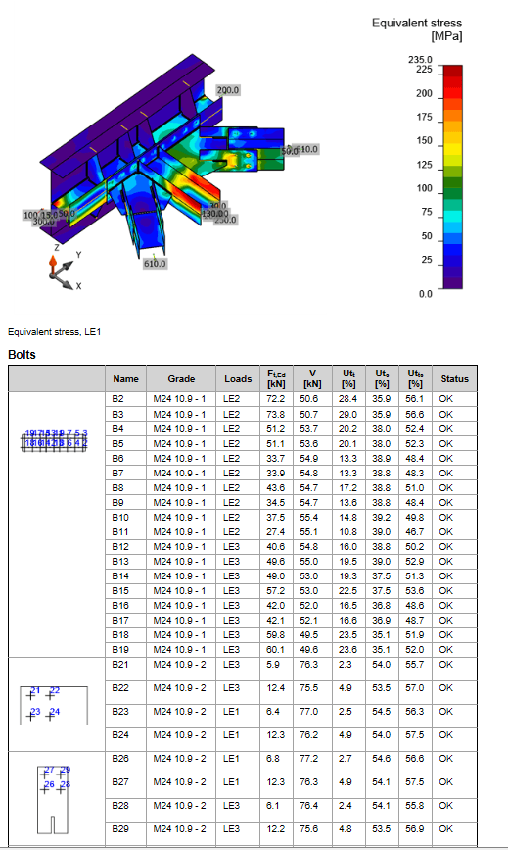

We combine two well-known and trusted methods used by engineers all around the world – finite element method

and component method:

Joint is divided into components

All steel plates are modeled by finite element method assuming ideal elastic-plastic material

Bolts, welds and concrete blocks are modeled as nonlinear springs

Finite element model is used for analyzing internal forces in each of the components

Plates are checked for limit plastic strain – 5% acc. to EC3

Each component is checked according to specific formulas defined by the national code, similarly as when using component

method

Validation and verification

Results of all tests performed to confirm safety and reliability of CBFEM method and IDEA StatiCa Connection are published

and available. Visit our website to examine them. Professor Wald and his team are also publishing a book devoted to structural

steel connections design using CBFEM method.

Benchmark cases for advanced design of structural steel connections

ACE-Hellas S.A.

Integrated Solutions